Have you ever used a nutraceutical supplement? If the answer is yes, the product probably features a bottle or blister packaging. Those are the most common ways of packing vitamins and other supplements. But have you ever wondered why manufacturers choose these methods? Are they easiest for them, best for the consumers, or both?

The truth is that the best choices in supplement bottle packaging only depend on the product. Some units are ideal for storing in bottles, but others might need an alternative package form. That is why it is vital to make the right decisions during the process.

Packaging form and design can affect your product’s quality, shelf life, and attractiveness to customers. [1] In this article, we are focusing on supplement bottles and blister packaging. We will describe the processes in detail so that you can get familiar with how packaging works.

What Should You Know About Blister Packaging?

Blister packaging is a versatile package form suitable for various products. That includes capsules and tablets, electronic accessories and goods (headphones, USD drives), toys, toothbrushes, DIY products, batteries, breakable products, etc.

If you haven’t used a supplement, you’ve surely bought several other products in a blister package so far. The process comes down to using heat to form a pocket or bubble (blister) in a plastic sheet. That is where the product comes, and the mold is then sealed to cover the item. [2]

The main idea of blister packaging is to keep the product safe. Since each unit is sealed, that offers almost total protection. That is the reason why supplement manufacturers often go with this form of packaging. It helps to keep the capsules or tablets uncontaminated and clean and keeps the package tamper-proof.

Apart from protection, blister packaging can have a visual impact and be attractive to consumers. Additionally, it secures a light packaging, which means that the package won’t add any significant weight to the product.

What Are the Main Components of a Blister Pack?

The main components of a blister package are: [3]

- Blister – it is a forming film that’s easiest to describe as a pocket where the manufacturer inserts the product.

- Backing – the name used for a foil that you use to stick over the blister’s back to seal the product.

The most common materials used for blisters include polypropylene, polystyrene, polyvinyl chloride, and mixtures of the mentioned components. [4] When it comes to backing, the manufacturers use aluminum foil, paper, or the combination of the two. It is also interesting to note that you can choose between peelable types, which are a child-resistance packing, and the push-through type.

Here is an overview of the materials and their suitability:

- PVC – it is a simple unit pack with a low barrier. You can use it for stable products like paracetamol and soft gelatin capsules.

- Aluminum foil – it features an excellent barrier and is suitable for strip packing of sensitive tablets and capsules.

- PVC/PVdC – these combinations feature a good barrier and might be suitable for enzyme/FDC products that are moderately sensitive.

A Step by Step Process of Making Blister Packaging

The steps involved in the formation of a blister might depend on various factors. However, we can divide the process into three main categories: [3]

- Thermoforming – This step involves getting a sheet made of thermoplastic resin material, and then using heat to soften it. After that, use vacuum molding to convert the plastic sheet you softened into a mold. Allow it to cool down and release the sheet from the mold.

- Filling – now that you have the sheet ready, you can fill it with capsules. The sheets move to the filling station where the capsules or soft gels are inserted.

- Sealing – the final part of the process is sealing. It involves lidding the sheet with a specific material, and it implies using the heat once again.

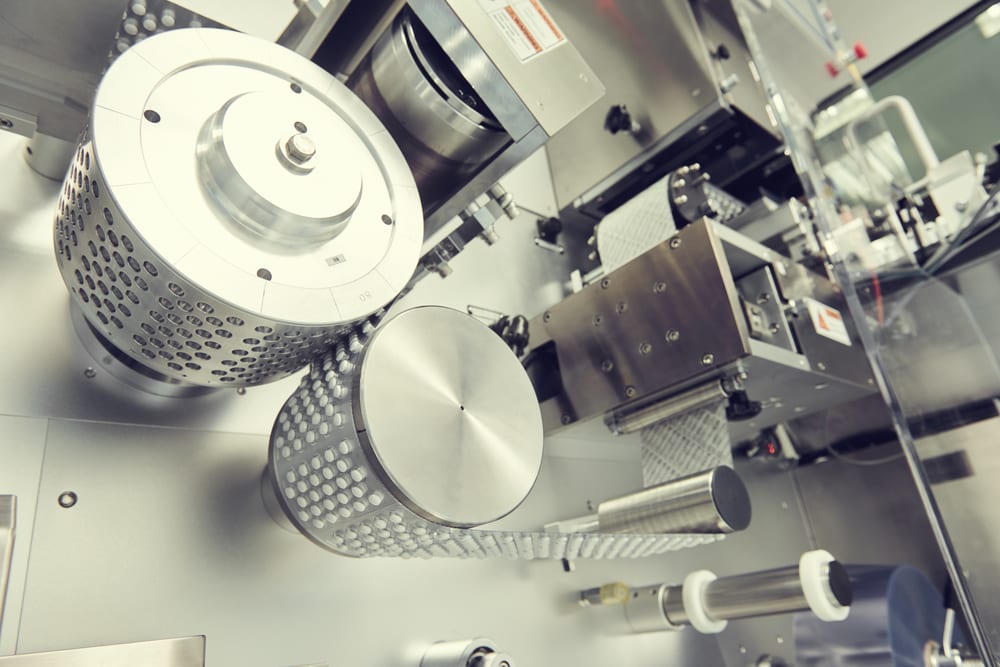

Check Out This Video Of A Blister Card Packaging Machine Working at SMP Nutra!

What Should You Know About Bottle Packaging?

While blister packages are very versatile in general, bottles have a high level of versatility within the nutraceutical and pharmaceutical industry. [5] That is because bottles are convenient to pack capsules and tablets, but also liquid and powder solutions. It provides the option for companies to add any type of product to bottles.

The materials used for bottles can vary significantly, as well as shapes and colors. When it comes to materials, the choice comes down to picking between glass and plastic. Glass bottles are often the primary choice for liquids as they feature excellent barrier in protecting the liquid.

However, plastic bottles are often used for capsules and tablets. The materials might vary depending on the application and include:[6]

- HDPE – it is high-density polyethylene, which has a decent moisture barrier. You can often find it in FDA-approved food-grade products.

- Polystyrene – manufacturers often use it for vitamins and other dry supplements. Although it is rigid and has decent barrier characteristics, its impact resistance is not that admirable.

- Polypropylene – an excellent choice for jars as it is rigid and moisture-resistance. However, it doesn’t perform well in cold temperatures.

- Aluminum – if your product requires it, you might even go with an aluminum bottle.

Apart from the material used for the bottle, you also need to determine adequate size. If you are manufacturing small capsules, you might not need a large bottle. The same goes if you are packing a compact testing pack with a limited number of pills. On the other hand, if you want to give the users an option to buy large packs and stock on the product for months, consider bottles with high capacity.

Check Out This Video Of Bottle Packaging At SMP Nutra!

The Importance of Using a Bottle or Tape Seal

If you want to increase tamper resistance to the highest level, you should consider using a bottle or tape seal. [3] A bottle seal is an excellent way to bond the bottle rim and the inner seal so that the only way to access the product is by destroying the seal.

As for tape seals, these involve applying pressure-sensitive or glued labels or tape over and around the closure of the package. Before you access the product, you have to destroy the seal. It is an excellent way to prove there was no tampering with the capsules.

A Step by Step Process of Bottle Packaging

Here is a short overview of the basic steps of bottle packaging.

- The first thing to do is to choose a suitable bottle. Once you pick the desired shape, color, and size, the company resorts to manufacturing those bottles. It is always wise to order as many bottles as possible at one as that might save you some money.

- Once the bottles are ready, it is time to fill them with capsules and tablets. That is something that is usually done at the filling station.

- After you load the specified number of capsules into the bottle, it is time to place the cap on top of it. The cap should already be designed to meet the needs of the customer and the bottle itself. Depending on the project, you might also need to add a seal to the bottle.

Other Packaging Considerations

The primary task of packaging is to protect the product and maintain its form and quality until it reaches the customer. However, it should also help potential users to identify the product easily, which means companies can use it to promote their supplements. [3] Here are some other considerations to keep in mind during the supplement bottle packaging process.

Secondary Packaging

If you are using bottles, you might not want to use a carton or box for your product. However, if you use blister packaging, it would be wise to use secondary packaging, too. That means you should choose and design a suitable box or carton that can keep multiple primary packages in a single place.

Tertiary Packaging

Additionally, consider tertiary packaging options. Those are boxes or other items used to deliver the product to the distributors or customers. Tertiary packaging is particularly important for bulk shipping and handling.

When choosing packaging options, always keep in mind how to reach the end-user. In some cases, products will travel long distances between the production point to the distributor and the ultimate consumer. It is your task to optimize the process to ensure the products are in perfect shape once it reaches the user.

Labeling

The label might be a crucial part of the packaging for dietary supplements. Since the product needs to be resistant to tampering, you should offer as much information as possible on the label. You should make sure to list the nutritional value and all the ingredients used. [1]

Other details should include the expiration date of the capsules, as well as other relevant information. If you obtained FDA approval, make sure to add the certificate to the label as that increases customer trust. You can also consider other indicators like the product being free from artificial fillers, or the capsules begin vegan or vegetarian-friendly. Finally, don’t forget to add the short instructions on how to use the product.

Start Your Own Private Label Supplement Line

SMP Nutra is qualified to manufacture any kind of nutraceutical formula. We are able to assist you in the entire process of manufacturing and we offer plenty of packaging options to choose from.

References:

- https://www.entrepreneur.com/encyclopedia/packaging

- https://www.we-pack.co.uk/advice-centre/guides/guide-blister-clam-packaging/#blisterpackaging7

- https://www.slideshare.net/bharathpharmacist/pharmaceutical-packaging-39636006

- https://www.slideshare.net/GirishSahu13/pharmaceutical-packaging-tablet-and-capsules

- https://en.wikipedia.org/wiki/Drug_packaging#Bottles

- https://en.wikipedia.org/wiki/Plastic_bottle