Call Us 24/7: (833) 810-9896

Your Nutraceutical Biotin Manufacturer

SMP stands for Supplement Manufacturing Partners. Our team is dedicated to be your partner in most efficiently manufacturing your growing vitamin business to scale.

Blending

Your biotin formula must be blended to ensure even distribution of ingredients in each supplement.

Bottle/Bag Filling

Once all ingredients in your formula are blended, they are filled in your bottle or bag of choice. We offer some amazing packaging options to fill your supplement with.

Polishing & Inspection

Each biotin bottle is polished for a clean finished look and triple inspected for any defects

Testing

After the supplement is manufactured, post-inspection, we run identity, potency, micro, and heavy metal tests to ensure pharmaceutical grade quality.

Our Capabilities

Custom Nutraceutical Biotin Manufacturing

We have capabilities to manufacture any nutraceutical biotin formula. From sourcing each ingredient in your formula, to post filling inspection; we do it all at the best prices and the fastest lead times. We have the experience to help you formulate a new product for your target audience, or discuss with you how to properly scale your manufacturing. As your partner, it is our job for long-term biotin manufacturing success.

Custom Biotin Manufacturing

Biotin has solidified its place in the supplement industry. From the beginning, white label biotin supplements were all the rage. Years later they are still around and have never been more popular. Here at SMP, we are experts in manufacturing any nutraceutical biotin formula.

Biotin Manufacturing Process

Biotin, also frequently referred to as Vitamin H, is a type of vitamin B which is soluble in water and used for different purposes. The main function of biotin is to ensure proper use of the body’s carbs, fats, and amino acids.

The manufacturing process for this specific ingredient can vary depending on the encapsulation type. With the emergence of gummy vitamins, some of the steps involved in manufacturing gummy biotin supplements includes:

Melding and preparation

Product molding

Solidification and removal

Packaging and shipping

Melding and Preparation

Manufacturing white label biotin supplements typically will begin with blending and preparation.

The process starts with the mixing of ingredients in a single source and blending everything to create a mixture. The mixture is the first composite stage of all the ingredients coming together to form a single, well-measured solution. This solution is then heated in a specialized pot to let the ingredients blend further. The process is continued until the mixture achieves a thick consistency, being just a little less solid than a paste.

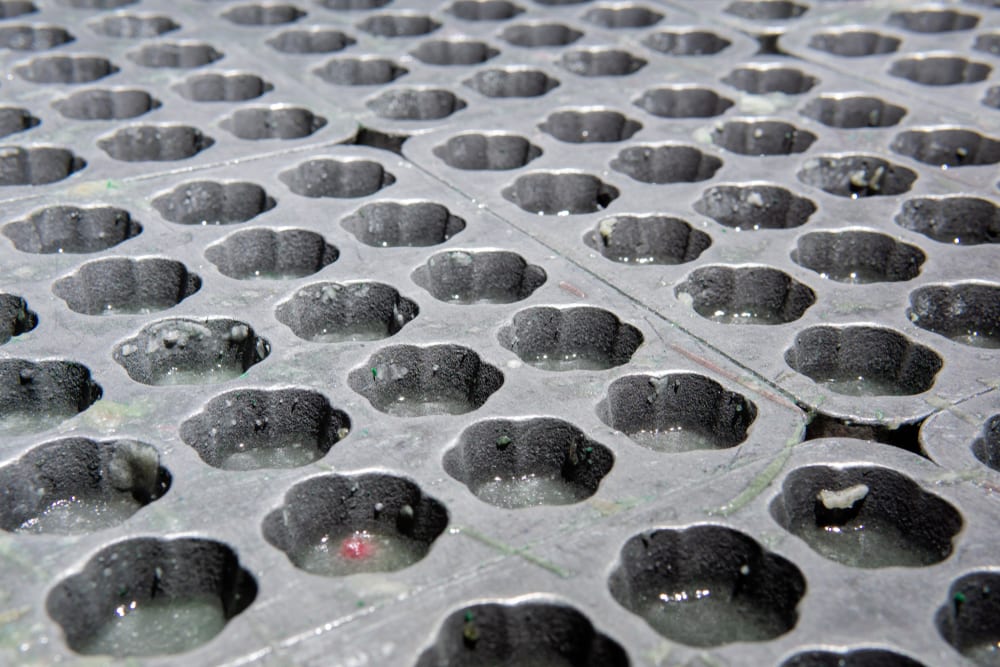

Product Molding

The right size and shape is crucial for a private label biotin gummy. The molding process is where this is achieved.

After the mixture is finalized, it is taken off the heat and cooled down. This is where the product needs to be given its final shape and for that, specially designed molds are used. The mixture is not poured directly to the molds as they could easily stick. To avoid that, a special medically safe coat is applied to the molds. This allows them to cool down the mixture without sticking and retain the desired shape. The molds create accurately measured pieces that are of the exact same size every time.

Solidification and Removal

Letting the gummies cool can effect the firmness and overall feel of the supplement.

Once the mixture is poured into the molds, the cooling process starts immediately. To make sure the product retains its consistency, the cooling is done slowly and the product remains in the molds for just over 24 hours. This provides sufficient time for the product to cool down and achieve its definitive shape. Once fully formed, they are poured into a huge tumbler from the molds. The large tumblers keep in spinning until the product is completely dry.

Packaging and Shipping

There are two types of packaging options that we provide; bags or bottles. The packing used for each product is according to the safety requirements for that particular product. Once the product is ready to be packed, it is poured into either bags or bottles, depending on the requirement. Each bottle and bag is properly labeled to include all the required information related to the product. The packaging quality is of the highest quality and ensures the product maintains its lifespan effortlessly. The sealed bags and bottles are then packed inside sealed cartons which we then ship to the specified destination.