Color

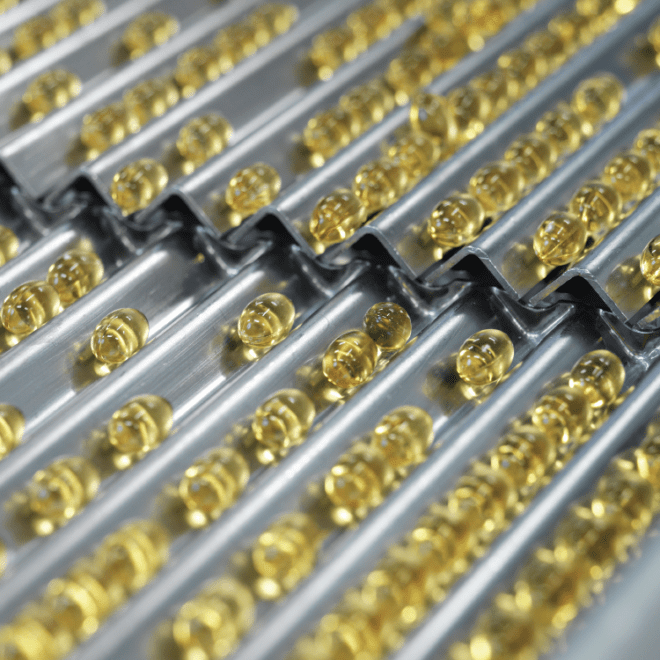

The color of a softgel can be modified to better match the contents of it.

Size

Produce the perfect sized softgels that are both easy to swallow and capable of delivering the formula's blend.

Diet-Friendly

Softgels can be made with vegan-friendly ingredients to reach a larger audience.