Call Us 24/7: (833) 810-9896

Your Custom Nutraceutical Capsule Manufacturer

SMP stands for Supplement Manufacturing Partners. Our team is dedicated to be your partner in most efficiently manufacturing your growing vitamin business to scale.

Blending

Before encapsulation, your formula must be blended to ensure an even distribution of ingredients in each capsule.

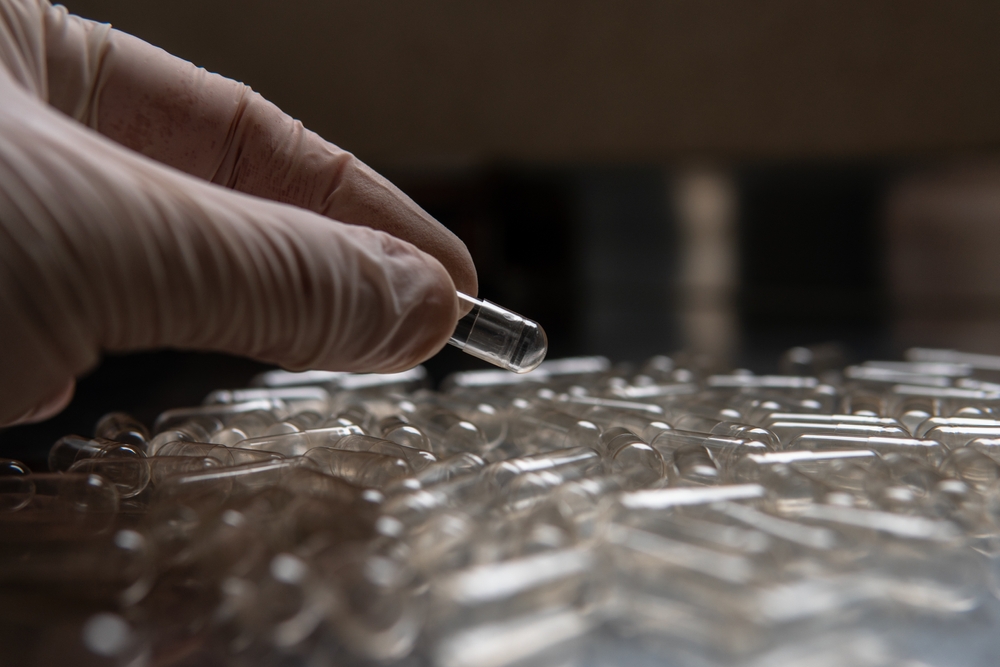

Encapsulation

Once all ingredients in your formula are blended, they are filled in capsule shells. Capsule shells are commonly made of gelatin, vegetable, or pullulan, depending on the formula.

Polishing & Inspection

Each capsule is polished of any excess powder for a clean and finished look, followed by being inspected for any defects.

Testing

After capsules are manufactured, post-inspection, we run identity, potency, micro, and heavy metal tests to ensure pharmaceutical-grade quality.

Watch How Capsules Are Manufactured

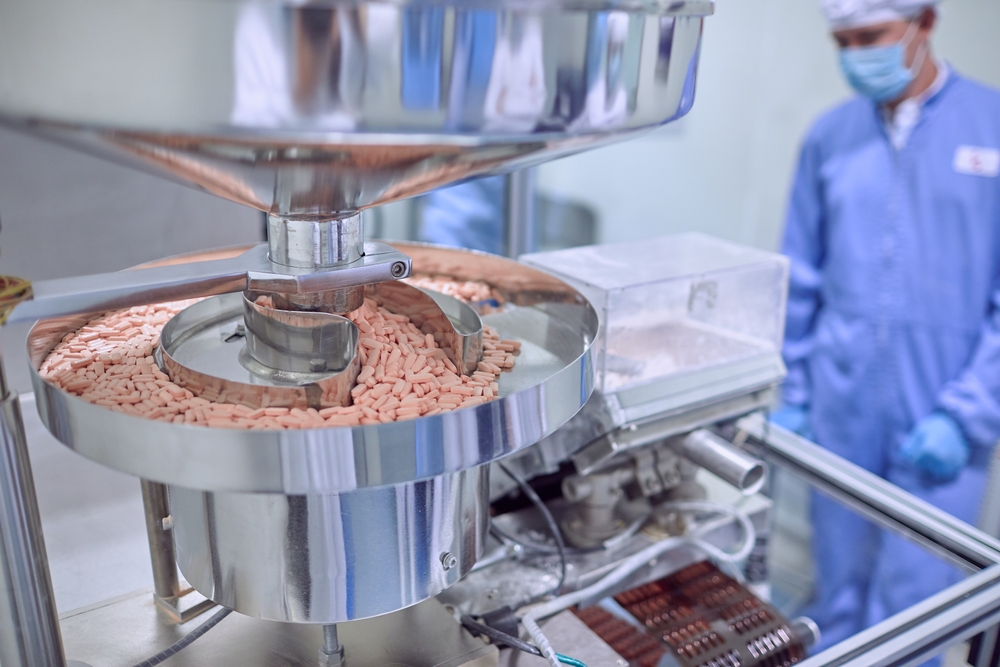

Our Capabilities

Custom Nutraceutical Capsule Manufacturing

We have capabilities to manufacture any nutraceutical capsule formula. From sourcing each ingredient in your formula, to post encapsulation inspection; we do it all at the best prices and the fastest lead times. We have the experience to help you formulate a new product for your target audience, or discuss with you how to properly scale your manufacturing. As your partner, it is our job for long-term capsule manufacturing success.

The Capsule Manufacturing Process

Capsules are one of the most versatile and most common forms of encapsulation for nutraceutical formulas. We can assist you with all of your stock or custom capsule manufacturing needs.

Capsule Blend Preparation Process

Before a capsule can be filled with its contents, there is plenty of work that goes into preparing the formula for encapsulation. The contents within capsules can be prepared by undergoing one of the following processes:

- Wet Granulation Process

- Dry Granulation Process

Wet Granulation Blend Capsule Manufacturing Water Phase

During the wet granulation process, you begin with the blend for the supplement ready and mixed. Then the mixed blend will then have water added to it.

The water will wet the powder which creates an immobile layer of water between particles. With more and more water being added to the powder, it will continually grow the layer of water gets wider and will ultimately pass through the pores of the particles.

Wet Granulation Blend Capsule Manufacturing Evaporation Phase

Now that the blend has had water added to it, the next step is to evaporate the water. This helps the blend to strengthen and bind together.

To then get the water out of the blend, it will be evaporated and will result in a very strong level of adhesion for the particles, which will result in the particles grouping in and becoming larger. The size of particles will be affected by many factors such as blend, density, and the type and amount of binders added.

Wet Granulation Blend Capsule Manufacturing Drying Phase

The drying phase is last in the wet granulation blend process. This allows for the blend to stay in place in the capsule and prevent it from spilling out.

The final step is drying. For small batches, a tray drying oven is used, but for more automation and larger batches, fluid bed dryers are used. These driers utilize a stream of warm and dehumidified air running through the base of the drying chamber. To keep the powder from being pushed out of the chamber, a fine mesh is in place to keep the powder in place.

Dry Granulation Blend Capsule Manufacturing

The process of dry granulation is commonly used when the product’s blend doesn’t behave properly when met with moisture and heat.

The main difference in this process is the fact that liquids are never introduced to the blend. With the prepared blend of ingredients, the powder will be fed into a machine that will apply immense pressure and force to make the powder more compact and increase the bulk density. The amount of force needed varies depending on the blend, its ingredients, and the desired density.

Capsule Encapsulation Process

Manufacturing a nutraceutical capsule is not done until the prepared contents are filled into the capsule.

When producing these capsules, the materials must be gathered. Once all materials are prepared, they are joined with hot demineralized water and mixed via vacuum, in a machine. Over time, the blend will have more hot water added, dyes and opacifants if needed. When ready, the mixture will be molded around steel pins into the correct size and shape of the capsule. Both ends of the capsule are then dried together. The level of the temperature and humidity are monitored to correctly allow for optimal drying of the capsules.

After the process of preparing and drying the capsule, the cap and body will be trimmed to a .15 mm tolerance. The capsules are put together and are ready to be filled and sent out.

Capsule Shell Options

Capsule shells are most commonly either made of gelatin or are vegetarian-friendly:

Gelatin Capsules

Gelatin capsules are created with resources from animals such as bones and cartilage. One of the most common resources for this type of capsule is bovine collagen.

Vegetarian Capsules

Vegetarian capsules are developed commonly with hypromellose, HPMC for short, or the water-soluble polysaccharide pullulan that is produced from the fermentation of starch.

Different Types Of Capsule Contents

Capsules are a versatile form of encapsulation as they are a suitable mode of transport for a range of contents. They are suitable for delivering liquids, powders, pellet blends, and more.

The contents of capsules may have an impact on the type of shell as some contents may only behave as expected in a certain capsule type.

Manufacturing Capsules With Special Attributes

Part of what makes capsules great is that they can be manufactured to behave differently. One of the most notable implementations of this is creating a delayed-release capsule to help deliver the contents of the capsule at the most optimal time.

Enteric capsules are another form of specialized capsule that can be made. These capsules are designed to withstand stomach acid so the contents of the capsule are released in the intestines.

SMP Nutra is equipped with the best machinery and team to manufacture any capsule supplement for your brand, with the highest quality.

Capsule Manufacturing FAQ

What is the MOQ for capsules?

The MOQ for gummies varies depending on whether the formula is a stock formula from SMP Nutra or a custom formula.

- MOQ for stock products is 1,000 bottles

- MOQ for custom capsules or tablets is 150,000 pieces ex 60ct 2,500 bottles

Why is gelatin used in capsules?

Gelatin is an excellent product for capsule manufacturing. It can protect the capsule contents from contamination, light, microbial growth, and other harmful factors.

Why should I choose capsules over tablets?

There are many situations where the formulation is better to be made in a capsule. Generally, capsules are easier to swallow and generally dissolve faster than tablets when ingested.

Should I choose gelatin or vegetable capsules?

This depends on the product that you are looking to bring to market. There are some customers have no preference between gelatin or vegetable capsules, while others specifically seek out products that contain one or the other.

Do you offer stock capsule formulations?

SMP offers a wide variety of top quality stock capsule formulas. Please contact us for any questions you may have about our stock options.