Call Us 24/7: (833) 810-9896

Your Custom Nutraceutical Gummy Vitamin Manufacturer

SMP stands for Supplement Manufacturing Partners. Our team is dedicated to be your partner in most efficiently manufacturing your growing vitamin business to scale.

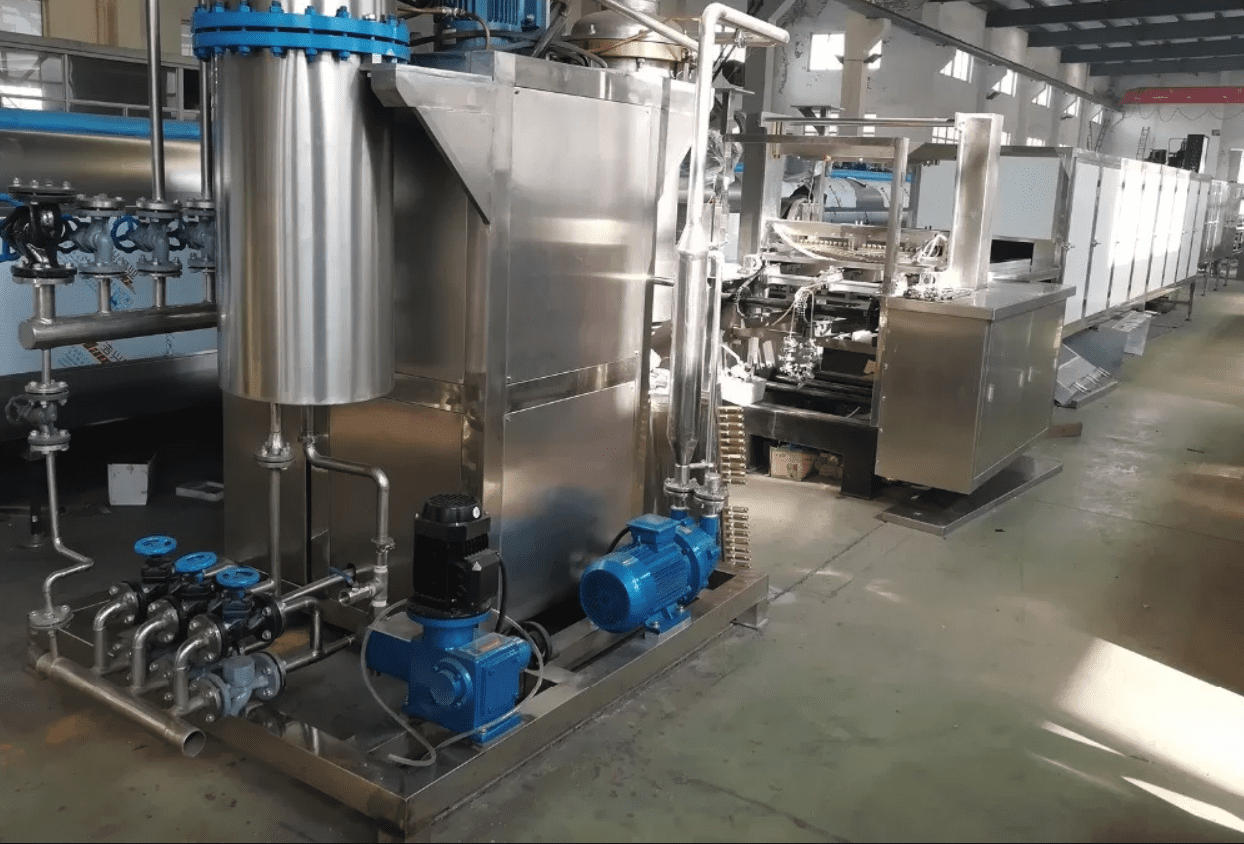

Mixing & Cooking

Ingredients are sourced and mixed to create a blend. Once ingredients are blended, the resulting liquid is cooked until it thickens into a “slurry.”

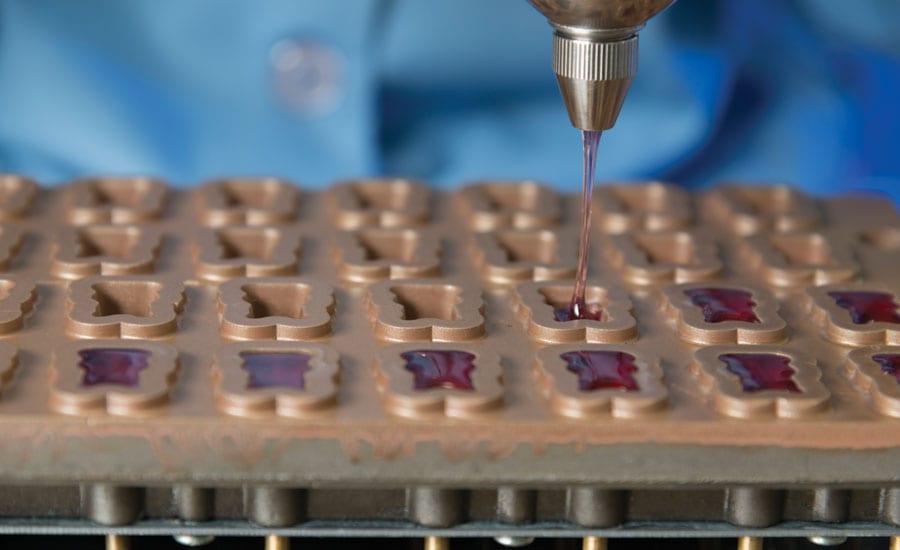

Molding

Before the slurry is poured, the molds are prepared to be resistant to sticking. The slurry is poured into the mold, creating a shape of your choice.

Cooling & Unmolding

After gummy vitamins are poured into the mold, it’s cooled to 65 degrees and set aside to sit for 26 hours to form and cool after the gummies are removed and placed in a large drum tumbler to dry.

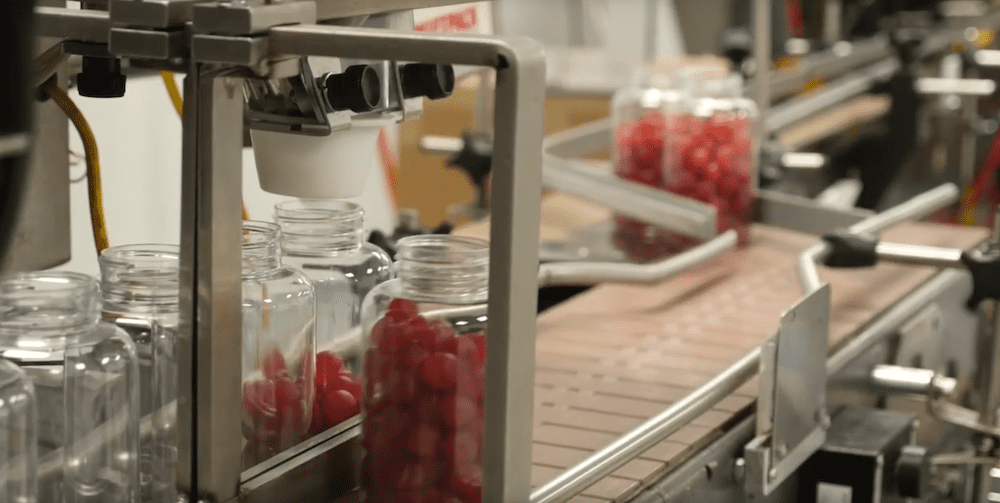

Bottle/Bag Filling

Once all your vitamin gummies are produced, they are filled in your bottle or bag of choice. We offer amazing packaging options to put your gummy vitamins in.

Watch How Gummy Vitamins Are Manufactured

Our Capabilities

Custom Gummy Vitamin Manufacturing

We have capabilities to manufacture any gummy vitamin formula. From sourcing each ingredient in your formula, to post filling inspection; we do it all at the best prices and the fastest lead times. We have the experience to help you formulate a new product for your target audience, or discuss with you how to properly scale your manufacturing. As your partner, it is our job for long-term gummy vitamin manufacturing success.

The Gummy Manufacturing Process

When producing gummy vitamins, it is obvious how much more arduous the process can be as opposed to other traditional vitamin manufacturing.

Gummy vitamins need to be a mixture of chewy, tasty, and still packed with the correct nutrients. These variables are sometimes tough to control, but once the process is done once, that outcome can be repetitively produced again and again.

Blending Your Gummy Formula

When producing gummy vitamins, it is obvious how much more arduous the process can be as opposed to other traditional vitamin manufacturing.

Gummy vitamins need to be a mixture of chewy, tasty, and still packed with the correct nutrients. These variables are sometimes tough to control, but once the process is done once, that outcome can be repetitively produced again and again.

Pouring Slurry Into Mold & Cooling

The slurry will then be poured into a mold. The mold can be of any shape, but most commonly, it is a bear.

Corn starch is applied to the molds prior to pouring the slurry to prevent the slurry from sticking. Now, with the slurry in the mold, the molds are brought to a temperature of 65 degrees and sit for roughly 24 hours.

Mix In Tumbler With Wax Or Oil

At this point, the slurry has formed into a solid. The gummies are removed from the molds and placed into a drum tumbler.

Also added to the tumbler is a food-grade oil or wax that will help the gummies stay soft and fresh. The gummies are now ready to be packaged and shipped. While the process of manufacturing a gummy vitamin is different, it does not make it any easier. With us as your partner, we are qualified to help you manufacture your gummy vitamins as a high-quality product.

Bottling & Labeling Gummy Vitamins

Once the gummy vitamins are in their final form, we distribute them inside their packaging accordingly.

Depending on your product, you will have a unique number of gummies inside each bottle/bag. We finish the gummy vitamin manufacturing process by distributing the gummies inside the packing, applying labels, and final sealing.

Completed Gummy Vitamin Delivery

At this point, your gummy vitamins are prepared to be shipped to a warehouse for storage.

As your gummy vitamin manufacturer, we can either send it to your warehouse or store it within our warehouse if the terms are agreed upon. Additionally, we offer fulfillment services for all orders placed for your products. Learn more about this today here.

Healthy Gummy Vitamin Options

Gummy vitamins can also be made to be halal, kosher, vegan or vegetarian friendly, sugar, and allergen-free. It is dependent on what kind of gelatin the gummy is made with.

A common way the vegan gelatin is made is with pectin. Pectin has a plant-based origin and is often used in jellies and jams. Even with the pectin, the gummy vitamins will come out colorful and tasty like the rest.

Halal Certified

Vegetarian

Kosher Certified

Sugar Free

Vegan

Allergen Free

Diverse Gummy Vitamin Flavors

One of the best aspects of gummy vitamins is the different flavors they can have. The perfect flavor for a formula can turn an alright formula into an excellent formula. SMP Nutra powers your imagination by supporting almost any flavor for a gummy.

Our selection of stock gummy formulas that we currently offer in our catalog has various flavors. We are confident you will find a flavor that fits your requirements, if not, we are able to formulate custom gummies with your desired flavor.

Apple

Lemon

Strawberry

Raspberry

Tropical

Mango

Various Gummy Vitamin Shapes

As your private label gummy vitamin manufacturer, we offer a wide range of gummy vitamin shapes. The shape of your gummies can be a great small detail that customers appreciate.

We currently offer over 300 stock gummy formulas with many different shapes. Some of these shapes include buttons, bears, and gumdrops. Not sure if we have the correct mold for a project you have in mind? Reach out to us for further assistance on that topic.

SMP Nutra Wants To Be Your Gummy Vitamin Manufacturer

When choosing the best gummy vitamin manufacturer, it can be tough to get a hold of them and then keep healthy communication. As one of the top USA gummy manufacturers, you are able to add a badge showcasing the product was put together in the USA.

Not only that, but we can supply bulk gummy vitamins and consistently do this. While we work as a contract manufacturer, we can make the process of producing your private label gummy vitamin as streamlined as possible with the most communication and quality results.

Gummy Vitamin Manufacturing FAQ

What is the MOQ for gummies?

The MOQ for gummies varies depending on whether the formula is a stock formula from SMP Nutra or a custom formula.

- MOQ for stock formula is 1,000 bottles

- MOQ for custom gummies is 500K-1 million pieces (depending on complexity of formula) ex 60ct 8,333-16,666 Bottles

Can I get 100 bottles of 15 different products to reach the 1,500-bottle minimum?

At this time, no, you can not do that. Our high-speed equipment is set to produce no less than 1,500 bottles per SKU of each product.

Can your gummies ship to warmer climates without melting?

Yes. Many of our competitor’s gummies are gelatin-based. These gummies, for lack of a better term, “sweat” and clump in higher ambient temperatures, particularly under longer time frames associated with long-distance shipping and storage. All of SMP Nutra’s gummies are pectin-based, which can withstand any temperature but should ship in temperature-controlled vessels at around 70 degrees fahrenheit.

Do you offer drop shipping services?

We do not offer drop shipping services.

However, if you are interested in starting your own brand we do offer fulfillment services to assist with your nutraceutical operation.

Can I order samples?

If you are interested in receiving a sample of a stock formula on the SMP Nutra site, you can purchase one. An account representative from SMP Nutra can also help you receive samples.

Check out our 300+ stock gummy vitamin formulas to get started in the process.