Call Us 24/7: (833) 810-9896

Your Custom Nutraceutical Tablet Manufacturer

SMP stands for Supplement Manufacturing Partners. Our team is dedicated to be your partner in most efficiently manufacturing your growing vitamin business to scale.

Blending

Before tablet pressing, your formula must be blended to ensure even distribution of ingredients in each tablet.

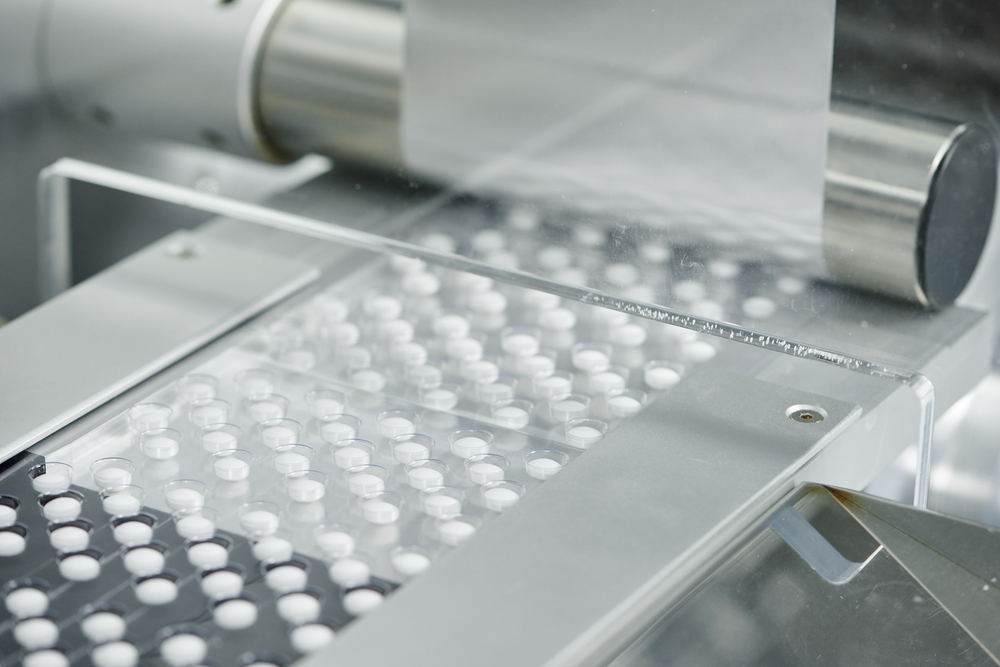

Tablet Pressing

Once all ingredients in your formula are blended, they are compressed into tablets. Tablets can have unique shapes and colors of your choice.

Polishing & Inspection

Each tablet is polished of any excess powder for a clean finished look and triple inspected for any defects.

Testing

After tablets are manufactured, post-inspection, we run identity, potency, micro, and heavy metal tests to ensure pharmaceutical grade quality.

Watch How Tablets Are Manufactured

Our Capabilities

Custom Nutraceutical Tablet Manufacturing

We have capabilities to manufacture any nutraceutical tablet formula. From sourcing each ingredient in your formula, to post tablet compression inspection; we do it all at the best prices and the fastest lead times. We have the experience to help you formulate a new product for your target audience, or discuss with you how to properly scale your manufacturing. As your partner, it is our job for long-term tablet manufacturing success.

Custom Tablet Manufacturing

Tablets are one of the most commonly used forms of encapsulation. They offer more customization and more possibilities for your formula and blend. Being one of the best vitamin tablet manufacturers, we are confident we can produce your private label tablet supplement at the highest quality.

The Tablet Manufacturing Process

Manufacturing the perfect tablet means it should contain the correct mix of ingredients, be made to a specific hardness so it can maintain its size and shape through strenuous bottling and shipping, and so it can have a long shelf life without worrying about any form of deterioration. The most common process to create tablets is known as direct compression.

Direct Compression Manufacturing

Direct compression is one of the more straightforward tablet manufacturing methods, as it has the least amount of steps. It is a process that has proven to be efficient and effective in producing high-quality tablets.

Ingredient Grinding

First, the ingredients are put through a grinder to produce a powder that can be used for the blending process that follows. A fine powder where the particles are the same size will be prepared to maximize the processes that will follow.

Blending

With the ingredients turned into a powder, the powder blend will now be put through a blender to ensure an even distribution of all the ingredients in the blend. At this stage any excipients or lubricants are added to the blend at this time, if needed.

Tablet Pressing

With the blend now mixed and ready to be made into the tablet itself, the next and final stop is a machine that will compress the tablets into the correct size and shape. After pressing, the tablets will be inspected and polished to remove any excess powder.

Bottling & Shipment

The tablets are now ready to be packaged into their appropriate form of packaging and be prepared to be shipped out. The tablet manufacturing process is now complete.

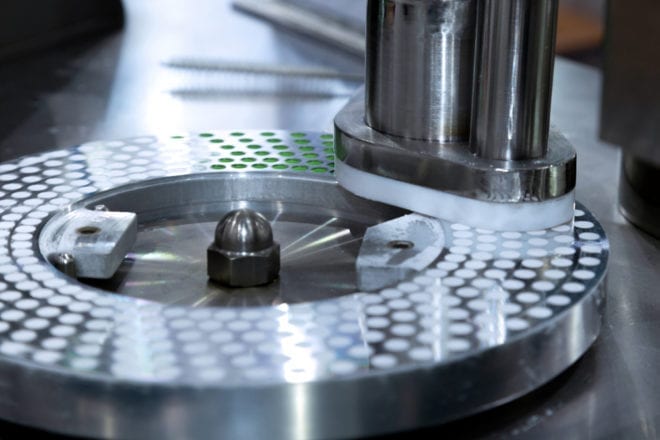

The Tablet Punching Machine

A Tablet Punching Machine Is Compromised Of A Few Parts:

Hopper

This is what holds the powder blend that is ready to be compressed. Hoppers come in a wide range of shapes and designs to assist flow.

Upper And Lower Punches

The actual action of pressing down on a tablet is done with the puncher. Both the upper and lower meet at the die to compress the tablet into that form.

Ejection Regulator

This enables the upper and lower punches to be adjusted. This allows for the fully made tablets to come to the surface of the dies.

Dies

This part holds the powder. It is also what helps to determine the size and shape of the tablet during the main process.

Cam Tracks

Guiding the puncher is necessary to get the desired results; the cam track is what guides the puncher. This allows for the punching machine to achieve maximum compression force.

Driving Wheel

To manually set the movement of the upper and lower punches, an employee can operate the driving wheel to set that movement.

Upper And Lower Turrets

These are parts of the machine that holds the upper and lower punches. Helps to to keep the compression parts accurate.

Capacity Regulator

Depending on the blend, the tablet may require more or less powder based on size and shape. This part of the machine regulates that amount of powder.

Discharge Chute

Collects the fully compressed tablets coming out of the take-off blade. Thus directing the tablets into a collection bin.

Different Types of Tablets

Compressed Tablets

Compressed tablets are perhaps the most commonly seen in the nutritional supplement market. These refer to the solid, oval-sized, or round tablet that you see in many everyday vitamins. These tablets are meant to be swallowed whole without breaking down or chewing.

Effervescent Tablets

An effervescent tablet is characterized by its ability to be dropped into a cup of water and dissolve within a matter of minutes. From there, the carbonated water can be consumed easily, and the contents of the tablet can be absorbed by the body.

Chewable Tablets

Chewable nutritional supplement tablets are very popular, especially in children’s and adult vitamins. These nutritional supplements are meant to be chewed so they will be broken up completely before they reach the stomach.

Fast Melt Tablets

Fast melt tablets, also known as sublingual tablets, are less common than other types of tablets and involve the placement of the tablet in a specific area of the mouth (either under the tongue or against the cheek) and waiting for it to dissolve. A sublingual tablet manufacturer has to follow a different process to make their tablets specific for each blend.

Private Label Stock Tablet Formulas

SMP Nutra Is Your Private Label Tablet Manufacturer

Choosing a tablet manufacturer can be a stressful process. When you choose us, the process will be taken care of completely. We are based in the USA and have a team that specializes in the production of nutraceutical supplements, including tablets. With fast lead times, clear communication, and great pricing, your tablet manufacturing will become streamlined.

Custom Tablet Manufacturing FAQ

What is the MOQ for tablets?

Stock tablets have a MOQ of 1,500 bottles. Custom tablet formulas have a MOQ that can be as low as 150,000 pieces ex 60ct 2,500 bottles, depending on the formula.

Do you offer stock tablet formulas?

We offer several various tablet formulas you can order today. You can view them here.

Do you offer label design services?

Yes, our team of in-house designers are experts in crafting nutraceutical supplement labels, including tablet product labels. Learn more about these services here.

Are there any ingredients that you can't or shouldn't use in tablets?

There are some hard to compress ingredients such as oils that would make creating a tablet difficult.

What does the term "granulation" mean in tablet manufacturing?

Granulation is the process that makes the powder form of ingredients larger so they’re easier to press into tablet form.